The Production Process

Our advanced production process ensures efficiency, precision, and high-quality output, meeting the diverse requirements of our customers.

- 1. Preform Feeding & Handling

- 2. Preform Heating

- 3. Preform Transfer & Pitch Change

- 4. Stretch-Blowing

- 5. Bottle Ejection

1. Preform Feeding & Handling

Preforms for bottle production are discharged in bulk from octabins into the preform hopper. An optional preform octabin tilter is available for standard and special preform containers. An ejection system ensures the removal of oval or improperly inserted preforms.

2. Preform Heating

The preforms are moved from the hopper to the linear preform unscrambler via an elevator belt, ensuring a uniform supply. The preform heating system uses laminar flow to evenly heat the preforms, preparing them for the blowing process.

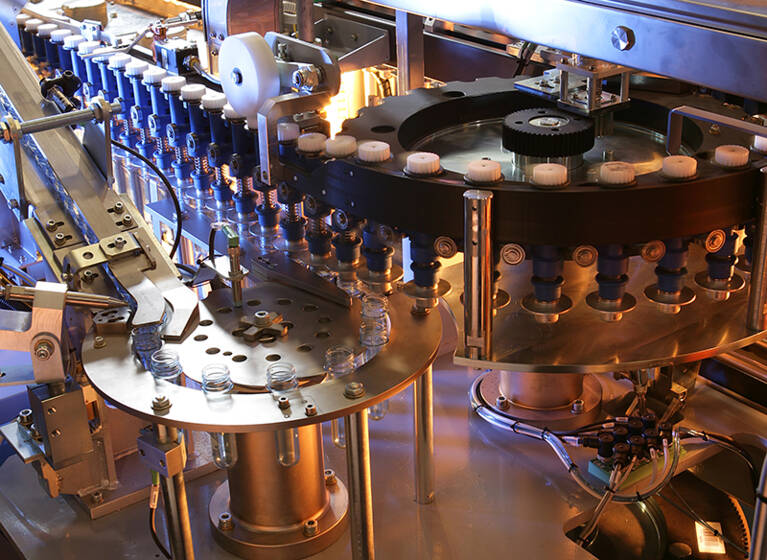

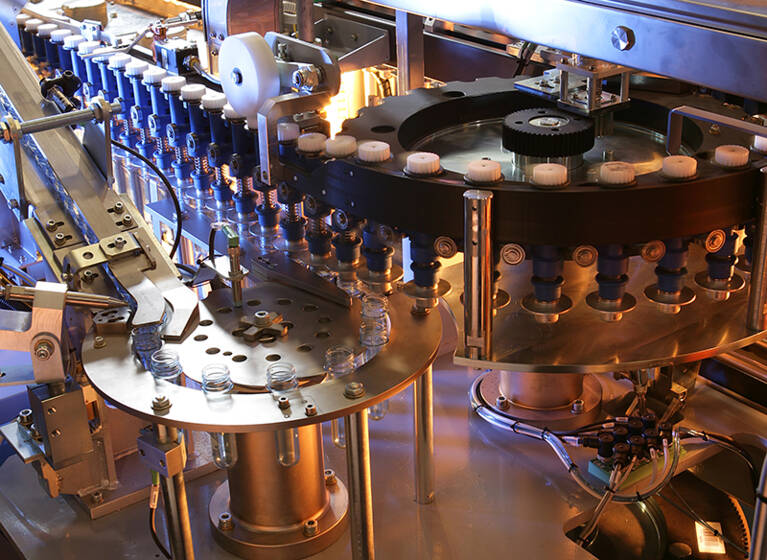

3. Preform Transfer & Pitch Change

The preforms are moved from the hopper to the linear preform unscrambler via an elevator belt, ensuring a uniform supply. The preform heating system uses laminar flow to evenly heat the preforms, preparing them for the blowing process.

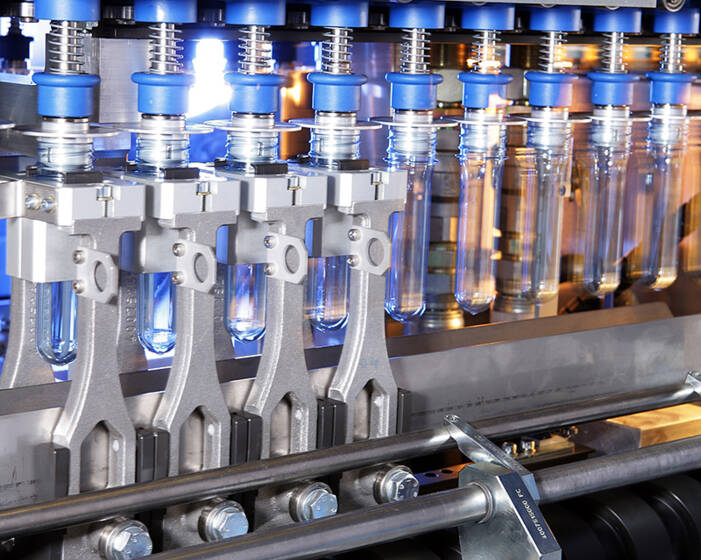

4. Stretch-Blowing

The stretch and blowing phase occurs within a fully electric blowing press. Axial stretching is carried out by servo motor-driven rods, enhancing repeatability and consistency. High-pressure air maintains the mould closed during the blowing process for optimal shaping.

5. Bottle Ejection

After blowing, the mould opens to release the blown bottles. These are evacuated by a linear transfer system integrated with the blowing press. An optional burst bottle system can discharge any unblown jars before they reach the conveyor belt. Various downstream evacuation systems are available based on customer needs, including air and belt conveyors.